What is the pigments? Know various types of Pigments

Are You Familiar With Pigments?

Pigments, also called colorants, give color to materials and are thus used as raw materials in many industries. It swaps the color of light thrown back through selective absorption of wavelength. Whatever you are seeing around yourself is painted with color. Though people often confuse pigment with dyes. But they are dissimilar to each other. The primary difference between colorants and dyes is in terms of their solubility. A dye is very soluble in any non-solid mixture and can easily dissolve in water and other liquids. However, this is not the case with colorants. A colorant can only dissolve in liquid only with the help of a binder.

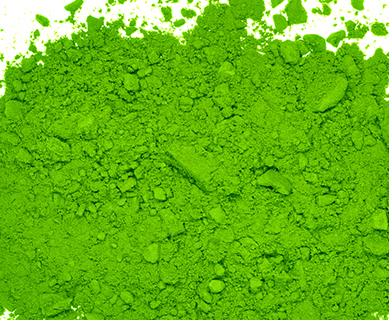

A colorant cannot destabilize itself in solid form at ambient temperature. It should have properties of high tinting strength. A particular application of any colorant depends on the physical properties of the colorant and its cost and requirements. The words rust stimulators and rust inhibitors have been taken from the words Pigment Green 7 and rust. Rust stimulators are the type of colorant that promotes active corrosion. However, the type of colorant that show the least corrosive properties are known as rust inhibitors. The types of colorants that lie between rust stimulators and rust inhibitors are called inert.

For industrial coating and uses, metal pigments are mostly used. Since colorants help protect metals from rust and corrosion, they are used to safeguard metallic surfaces. Color is the most vital criterion of selection for emulsion paints or varnishes. Similarly, for metal coatings, the most important criteria for choosing a colorant are the feature of having corrosion resistance. Colorants are used not as solutions but as finely ground solid particles. Similar colorants are used in oil-based and water-based paints, plastics, and printing inks. Colorants with an intense hue are used to provide color to other materials.

Let Us Have A Detailed Analysis Of Organic Pigment

Like inorganic materials, organic materials have been used to provide colors for thousands of years. Anyone who is a nature lover and works closely with plants knows that they are quite popular for ruining one's clothes and dresses. And one turned this observation into a well-intended process. The first organic colorants known to mankind were composed of carbon, hydrogen, nitrogen, and oxygen. They were generally harvested from nature as animal products or natural plants. Sometimes atoms of phosphorus and sulfur were also present in these organic colorants.

The organic colorant is generally transparent or colorless. The most common characteristic among all organic colorants is their ability to have several multiple bonds adjacent to one another. Examples of organic colorants include Saffron, annatto, and lycopene. Lycopene gives the tomatoes their red color. At the same time, Saffron is a yellow compound taken from the yellow hue of crocus stamens. Another example of an organic colorant is indigo. Indigo is mainly harvested from Indigofera tinctoria, a plant from subtropical areas in Asia. They are mainly used for providing blue color to jeans. Tyrian Purple, also known as the Royal Purple, can only be afforded by rich and wealthy-class people. They are mainly to provide color to the garments. Tyrian Purple is garnered from sea snails through a labor-intensive and expensive process.

Let Us Discuss Inorganic Pigment

Inorganic colorants do not form based on carbon chains and rings. They are usually made of dry ground minerals, generally metallic salts, and metals. The composition of metallic salts and minerals makes them opaque and insoluble in liquid without a binder. The low cost of inorganic colorants and their high resistance to sunlight makes them a very popular choice. Therefore, they are used more in industries as compared to organic colorants. The most vital benefit that you get when using inorganic Pigment Green 7 Manufacturer is that they are extremely resistant to light. The fade-resistant feature of inorganic colorants is used as raw material during the various manufacturing process in industries. They do not easily lose their brilliant color and hue when exposed to open air and heat.

Relatively simple chemical reactions are used to produce inorganic colorants. Thus, they are cheaper to manufacture in industries when needed in large quantities. The most commonly used inorganic colorant is Titanium dioxide. They are widely used for their excellent quality of color, reasonable cost, and nontoxic nature. Titanium dioxide also possesses high hiding power and is available at a very reasonable cost.

Uses Of Other Inorganic Pigments

White Extenders – are generally employed in industries to enhance certain materials features while keeping the costs to a minimum. Examples of white extenders are calcium sulfate, China clays, and calcium carbonate.

Black Pigments – are generally produced from carbon particles. For instance, the most commonly used colorant for black printing inks is carbon black.

Iron-Oxide Earth Pigments – are made of oxides and oxide hydroxides of iron. Iron-oxide earth colorants are responsible for producing earthy ochres, umbers, and siennas. These particles are commonly found in paints. The red-tone colors like sienna are obtained from Hematite, the most commonly used iron oxide. Yellow-tone ochres are composed of Hydroxide goethite. Brown-tone umbers are obtained from oxides of iron and manganese.

Cadmium Pigments – are used to manufacture a range of hues such as yellow, orange, red, and maroon. Cadmium colorant is primarily used to provide color to plastics. They are also used to color ceramics, glass, and paint.

Organic and inorganic colorants are quite different from each other. For instance, organic colorants have better color and hue when compared to inorganic colorants. But the color of inorganic colorants tends to last longer. Again, it is cheaper to produce inorganic colorants due to their relatively simple chemical reaction. There are two different types of colorants. It all depends on the needs of industries and manufacturing units!